Our Products

Factory For 6.38 Laminated Glass Price - Ceramic Glass Panel For Induction Cooker – Hongya

Factory For 6.38 Laminated Glass Price - Ceramic Glass Panel For Induction Cooker – Hongya Detail:

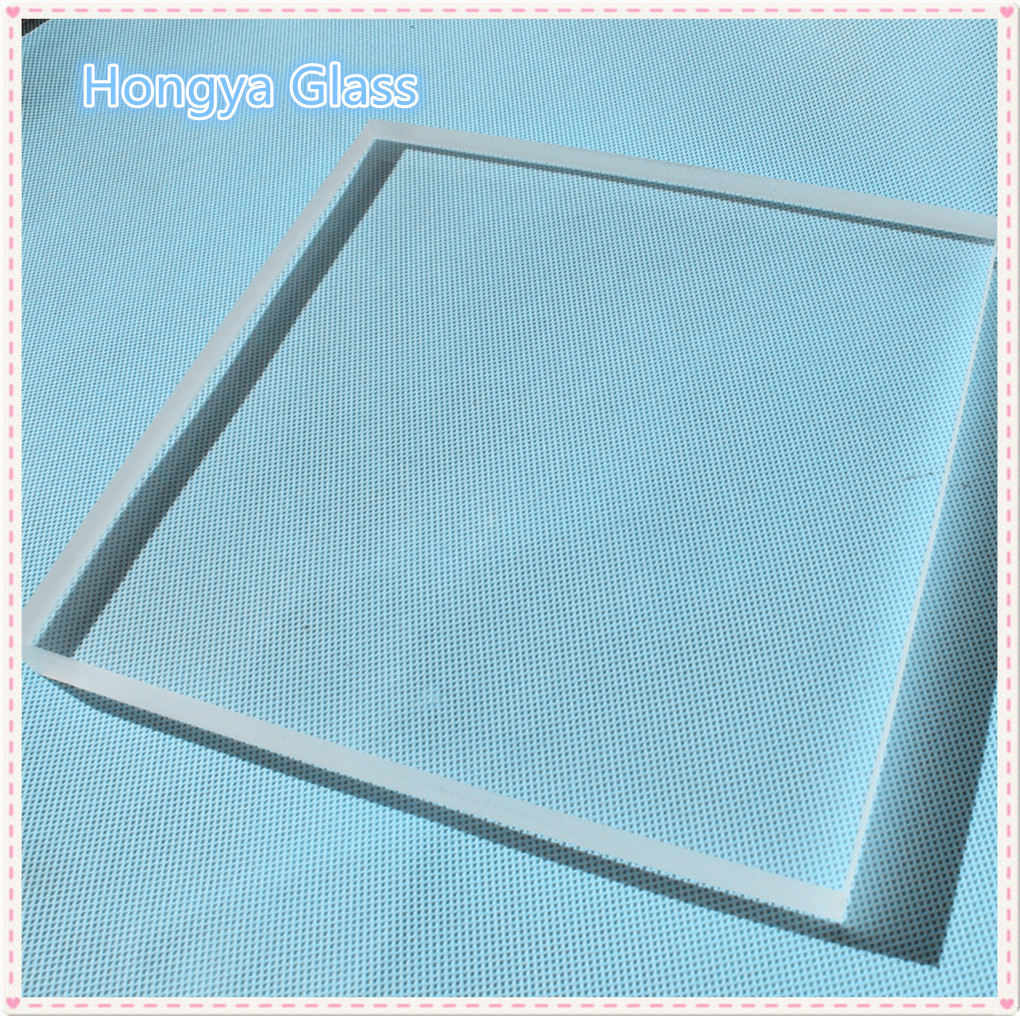

Ceramic Glass Panel For Induction Cooker/Glass Panel For Induction Cooker/Ceramic Glass Panel

(Ceramic Glass) Crystallite glass is made of a special glass ceramic, a material with fascinating properties. This glassceramic has extraordinary thermal stability and resists thermal shocks of up to +700 degree C. It standsup to everyday wear and tear in the kitchen. The 4mm thick cooktop panel transmits heat very efficiently, with virtually no heat loss.

Glass ceramic is resisting to heat and cold, even to extreme temperature changes.This extraordinary property enables a variety of applications: cooking on glass ceramic appliances day after day , and protecting your fire places or stoves, still enjoying flames view.

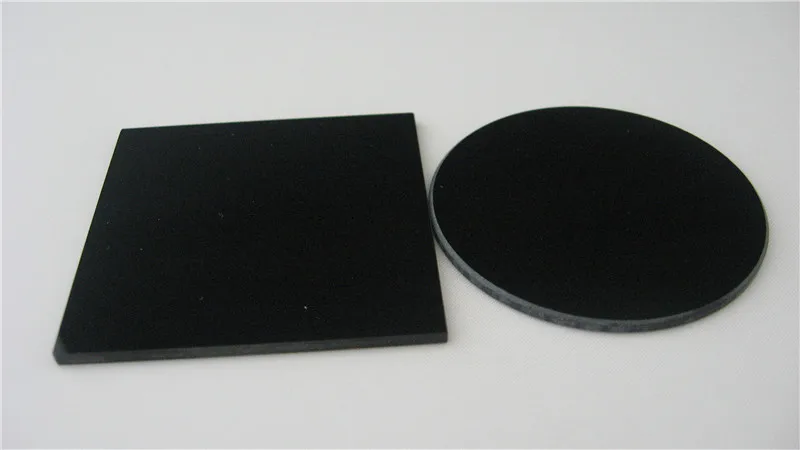

Among the heat resistant glasses, glass ceramic is really special. Its key property, is low thermal expansion, lower than borosilicate glasses or standard glasses. It means that, unlike most materials, the crystallite glass ceramic will not expand nor contract with heat. It barely changes its dimensions. This is the reason behind efficientand long time resistant cooktops.it’s colour have:black,white and clear.

- Model Number: Ceramic Glass Pannel For Induction Cooker

- Function: Heat Absorbing Glass, Decorative Glass, Heat Absorbing Glass and so on

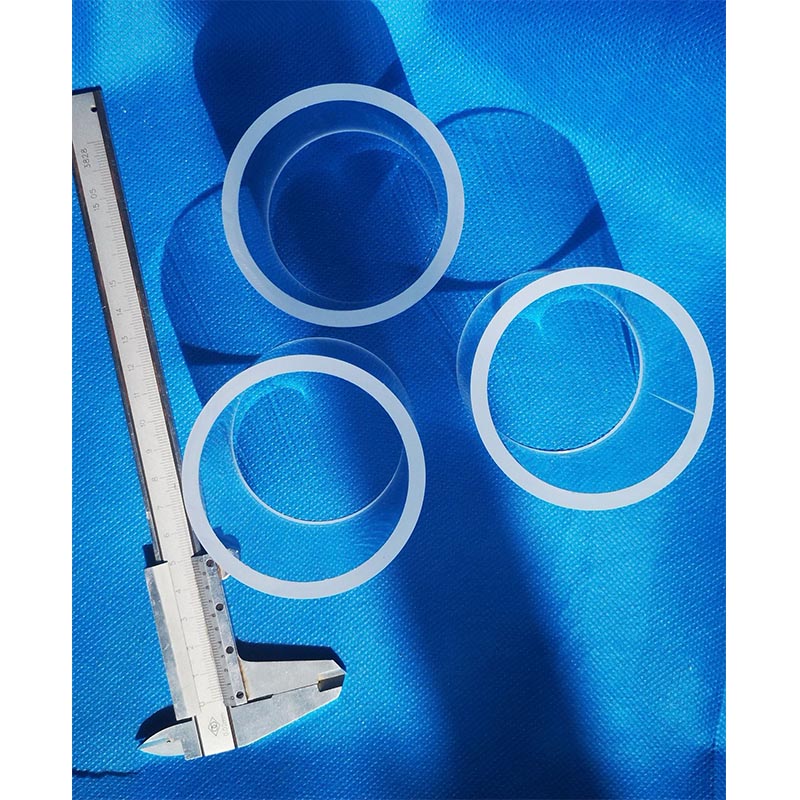

- Shape: Flat, Curve, Flat, variety of shapes

- Structure: Solid, Solid

- Technique: Clear Glass

- Type: Sheet Glass

- Color: Transparent, Black

- Application: fireplace,furnace,cooktop,induction cooker

- feature: could customize based on your demand

- Supply Ability: 100000000 Piece/Pieces per Month Ceramic Glass Panel For Induction Cooker

- Packaging Details: Each piece separated with pearl cotton, bubble big packing. Outside wooden box protect

- Port: qingdao

- Ceramic Glass Pannel For Induction Cooker/Glass Pannel For Induction Cooker/Ceramic Glass Pannel

1) mensions: 330*410,540*620,2000*1100 and deep processing according to requirement

2) ailable thickness: 4mm,5mm

3) Net sized glass of strengthening can be supplied as per the customers requirement;

4) Glass of small cut size is available according the requirement from customers.Other Application:

1). Household electrical appliance (panel for oven and fireplace, microwave tray etc.);

2). Environmental engineering and chemical engineering (Lining layer of repellence, autoclave of chemical reaction and safety spectacles);

3). Lighting (spotlight and protective glass for jumbo power of floodlight);

4). Power regeneration by solar energy (solar cell base plate);

5). Fine instruments (optical filter);

6). Semi-conductor technology (LCD disc, display glass);

7). Iatrology and bio-engineering;

8). Safety protection (bullet proof glass)Produce processing

Raw material→ Melting(under 1700 centigrade) → Shaping → Annealing → Crystallization → Processing → Cutting → Polished → Silkscreen(if needed) → Printing bending(if needed) → Inspecting → Packing

Further Process

Cutting,Round corner,Round edge,Surface fine polishing,Hole drilling,Coating,Surface printing and sand blasting,Thermal bending .

Product detail pictures:

Related Product Guide:

How can anything rival the threat of climate change? | 6mm 8mm 10mm Black Tinted Tempered Glass For Table Top

Review: iPad 4 has processing power to spare | 1.7 Mm Aluminum Mirror Glass For Cosmetics

"Quality 1st, Honesty as base, Sincere company and mutual profit" is our idea, in an effort to create consistently and pursue the excellence for Factory For 6.38 Laminated Glass Price - Ceramic Glass Panel For Induction Cooker – Hongya , The product will supply to all over the world, such as: Victoria, Seattle, Portugal, Our tenet is "integrity first, quality best". We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed