Our Products

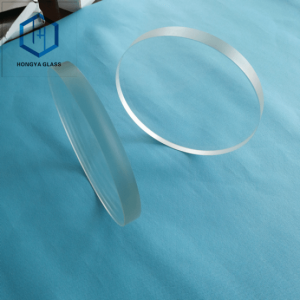

Borosilicate glass round sight glass

Product Detail:

3.3 borosilicate thermal shock float glass (can replace SCHOTT trademarks borofloat ® 3.3, CORNING trademarks pyrex ®7740) is produced using the float process, sodium oxide (Na2O), boron oxide (B2O3), silicon dioxide (SiO2) as a basic ingredient in the glass sheet.

Size:Customized size availale

| Physical Property | |||||||||

| No. | Physical performance | Numerical Value | Unit | ||||||

| 1 | Coefficient of mean linear thermal expansion(20°C,300°C) | 3.3±0.1 | 10-6K-1 | ||||||

| 2 | Transformation temperature | 525±15 | °C | ||||||

| 3 | Softening point | 820±10 | °C | ||||||

| 4 | Working point | 1260±20 | °C | ||||||

| 5 | Density at 20°C | 2.23±0.02 | g/cm3 | ||||||

| 6 | Mean thermal conductivity(20°C-100°C) | 1.2 | w/m2k | ||||||

| 7 | Refractive index | 0.92 | 1 | ||||||

| Main Composition | |||||||||

| SiO2 | B2O3 | Na2O+K2O | Al2O3 | ||||||

| 81 | 13 | 4 | 2 | ||||||

| Chemical Property | |||||||||

| Hydrolytic resistance at 98°C | ISO719-HGB 1 | ||||||||

| Hydrolytic resistance at 121°C | ISO720-HGA 1 | ||||||||

| Acid resistance Class | ISO1776-First Class | ||||||||

| Optical Property | |||||||||

| Refractive: | nd : 1.47384 | ||||||||

| Light transmission: | 92%thickness≤4mm91%(thickness≥5mm) | ||||||||

Application :

1. Household electrical appliance (panel for oven and fireplace, microwave tray etc.);

2. Environmental engineering and chemical engineering (lining layer of repellence, autoclave of chemical reaction and safety spectacles);

3. Lighting (spotlight and protective glass for jumbo power of floodlight);

4. Power regeneration by solar energy (solar cell base plate);

5. Fine instruments (optical filter);

6. Semi-conductor technology (LCD disc, display glass);

7. Medical technique and bio-engineering;

8. Safety protection (bullet proof glass)

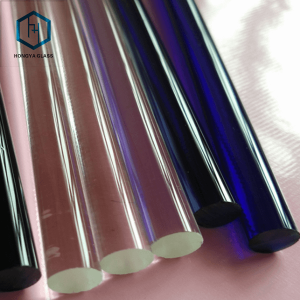

Products Show:

HOT-SALE PRODUCT

Quality First, Safety Guaranteed