Our Products

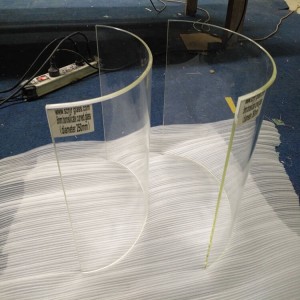

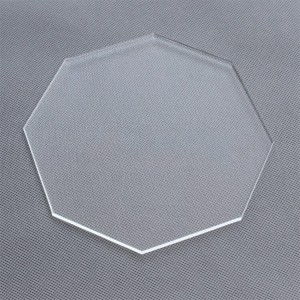

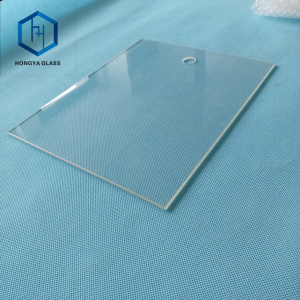

3D Printer Parts Borosilicate glass Plate for 3d printing size 257*229*4mm for UM2 printer

3D Printer Parts UM2 Borosilicate Glass Plate With 257*229*4mm for Ultimaker 2 3d printers

Our advantage:

1.High quality

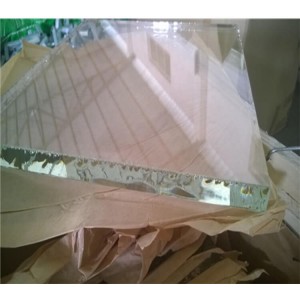

2.Professionally packed in wooden boxes to prevent the damages during the transportation

3.Customize any size you need.

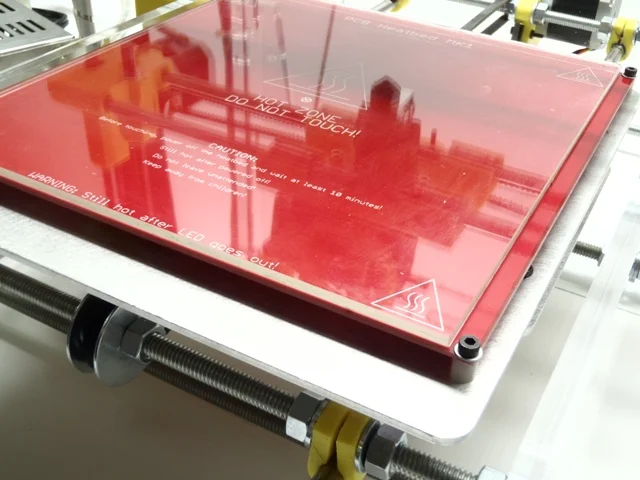

Glass plate with MK3 aluminium heated bed

PCB heatbed with glass board

Borosilicate glass 3.3 is one of transparent colorless glass, through wavelength is between 300 nm to 2500 nm, transmissivity is more than 90%. Coefficient of thermal expansion is 3.3. It can acid proof and alkali , the high temperature resistant is about 450°C. If course handling , the high temperature resistant can reach 550°C or so. Apply to lighting fixture , chemical industry , electron, high temperature equipment and so on.

Borosilicate glass 3.3 has excellent transmission over the visible and NIR wavelengths working from 310nm to 2700nm. The surface quality is not as high as the BK7 versions.

Borosilicate glass 3.3 has excellent chemical and thermal-shock resistance and has a maximum working temperature of 500°C so are excellent for use in high powered light source applications or an excellent choice for cold and hot mirror substrates..

Borosilicate glass 3.3 specifications

|

Product Name

|

Borosilicate glass

|

|

Density:

|

2.23± 0.02g/cm3

|

|

Hardness

|

>7

|

|

Tensile strength

|

4.8×107Pa(N/M2)

|

|

Bulk modulus

|

93×103 M pa

|

|

Modulus of rigidity

|

3.1×1010Pa

|

|

Young’s modulus

|

63KN/mm3

|

|

Compressive strength

|

1200kg/ cm2

|

|

Poisson’s ratio

|

0.18

|

|

Thermal expansion coefficient

|

(0-300℃) (3.3±0.1)x10-6K-1

|

|

Coefficient of thermal conductivity

|

1.2W×(m×k) -1

|

|

Specific heat capacity

|

(20-100℃) 00.82kJx(kgxk)

|

|

Softening point

|

810±10 ℃

|

|

The resistivity1gρ

|

250℃ 8.0Ω×cm

|

|

Dielectric coefficientε

|

4.7

|

|

Dielectric strength

|

5 ×107V/M

|

|

Dielectric loss factor

|

tanσ(MC20℃)≤38 ×10-4

|

|

Resistance to cold and hot shock

|

280℃

|

|

Continuous working temperature

|

≤550℃

|

Optical performance of borosilicate glass

|

Light transmittance

|

92%

|

|

The refractive index

|

1.47384

|

|

The wavelength

|

435.8nm=1.481, 479.9nm=1.4772 , 546.1nm=1.4732

|

Borosilicate glass application

Chemical industry

Food package

Medical packaging

Substrates for dielectric coatings

Lighting applications

Optical filter coating substrates

Wafer substrates

Anodic bonding applications

Biotechnology

Photovoltaics

Environmental technology

Harsh environments

Neutron absorbers

Measurement and sensor technology

Sight glass and optical glass

HOT-SALE PRODUCT

Quality First, Safety Guaranteed